1 Although air agitated leach tanks were commonly used in. 100TD gold tailing vat leaching line zinc wire displacement I.

Leaching Tank 3d Cad Model Library Grabcad

27 rows Leaching Tank Introduction Cyanide leaching stirring equipment.

. The goal of any leaching process is to selectively bring a desired mineral into solution in order to efficiently separate it from the solid waste material. - To get more agitation the impellers were sped up. For the pilot scale test work the plan was to feed ore into the vat at high.

The mineral industry has been using cyanidation to recover gold from ores for more than a century. This design problem caused solids to build up around the walls and bottom of the leach tank reducing the effective size of the tank and lowering the actual leaching time for the active slurry. The Leachox Refractory Gold Process The Testing.

My home made leaching tank was made March 2014 for handling small quantity of Gold Stone working together with some technique like Carbon System_Electrolys. In vat leaching typically a coarser material is placed in the vat for leaching. This leaching tank is designed to mix gold particles inside the slurry with carbon and cyanide in CIL plants.

Leaching plants faced with increased tonnage coarse up to 316 solids feed longer retention time erosion corrosion and the high cost of space must be compact simple and highly efficient. Leaching agitation tank is a leaching equipment for cyanide leaching by referring the USA technical design. The impeller coated by rubber long service life.

Leaching Plant Design. The leaching of gold can be conveniently represented by the Elsener equation. The number of carbon adsorption tanks.

In tank leaching the material is ground sufficiently fine to form a slurry which can flow under gravity or when pumped. Leaching agitation tank for gold extraction with double impeller uniform mixing low energy consumption. Volume 6-1740m3 Application Double impeller leaching stirred tank is suitable for gold leaching adsorption and other mixing operations with small specific gravity low viscosity slow settling speed ore particle size more than 90 in 200 mesh and pulp concentration less than 45.

In tank leaching the material is ground sufficiently fine to form a slurry or pulp which can flow under gravity or when pumped. The impeller coated by rubber long service life. Multi points to give gas.

Gold CIL Carbon in Leach Process is an efficient design of extracting and recovering gold from its ore. Cyanide tank construction Cyanide tanks are the main facilities for tank leaching process. It has become the first choice of modern gold mining and beneficiation.

This speed increase. Leaching agitaion tank is a leaching equipment for cyanide leaching by referring the USA technical design Capacity. Takes place in a series of agitated leach reactors or pachucas.

INNOVAT Continuous Vat Leaching plant design begins with bottle roll tests and proprietary column tests. In a tank leach the slurry is moved while in a vat leach the solids remain in the vat and solution is moved which reduce wear and tear of tanks. Acts similar to a capacitor in that small pumps operate.

This leaching tank is designed to mix gold particles inside the slurry with carbon and cyanide in CIL plants. We now have 3D films the 3D printer but most of all we provide the 3D nails. Add cyanide solution into first one or two leaching tanks add activated carbon into the rest gold leaching tanks.

Open tank leach processes a natural progression has been to further accelerate leach kinetics through the use of MMS leach columns. CONTINUOUS VAT LEACHING FIRST COPPER PILOT TRIALS. Pump slurry ore into the double-impellers leaching tanks there are always 6-8 tanks working togheter.

Leaching tank is one of the key equipment in agitation leaching process. Where agitated tanks must provide enough power constantly. Activated carbon adsorb gold and become the loaded gold carbon the loaded gold carbon lift into the.

Have discussed the systematic design and optimization of. From the results of the investigation the tanks-in-series model with. A typical installation is depicted in Figure 30 below.

This reduction in leach time ultimately resulted in lower gold recovery. In order to validate design data after process intensification at Damang gold processing plant experimental RTD investigation was conducted in a series of gold leaching tanks. With the development of science and technology its size is becoming larger and larger and its functions are becoming more and more perfect.

Leaching tank STEP IGES 3D CAD model GrabCAD. Tank leaching is usually differentiated from vat leaching on the following factors. Of a cascade of three equal-sized leaching tanks which was.

I-131 radioactive tracer was used to meas-ure the RTD of aqueous phase in the tanks. Before leaching the pH of the pulp is normally adjusted to a value of around 9511 to ensure minimum loss of cyanide as hydrogen cyanide. The engineer faced with the obvious economy of using a few large agitators compared to many smaller units must also.

By cyaniding and carbon leaching the gold ore slurry simultaneously CIL process lower the gold mining operation cost and increase gold recovery rate to a ratio of 98. As the key equipment in agitation leaching process the leaching tank needs to be designed. The percentage gold leaching that occurs prior to the first car- bon adsorption tank 100 assumed for CIP designs.

Enviro-Septic amp Simple-Septic Leaching Systems. Its for gold extraction with double impeller uniform mixing low energy consumption. Gold leaching tank design.

Gold Leach Tank Aeration Gold Leaching Gas Injection and Bubbles The processing of low-grade gold ores is largely made possible through the use of the cyanide leaching process. Simulation study of the optimal distribution of cyanide in a. The nail design Local community has long gone this much and truly attempted to make this kind and it thoroughly worked With a nod to modern artwork and graphic shapes black nail polish turns into an true function of art.

The Leachox Refractory Gold Process The Testing Design Installation and Commissioning of a Large Scale Plant at the VASGOLD Gold Mine Kazakhstan. In vat leaching typically a coarser material is placed in the vat for leaching this reduces the cost of size reduction.

Radiotracer Investigation In Gold Leaching Tanks Sciencedirect

Leaching Tank 3d Cad Model Library Grabcad

Leaching Agitation Tank Gold Leaching Cyaniding Equipment Well Tech International Mining Equipment

Pdf Improving The Process Performance Of Gold Cyanide Leaching Reactors Semantic Scholar

How Leaching Agitation Tank To Help Customers Extract Gold Xinhai Youtube

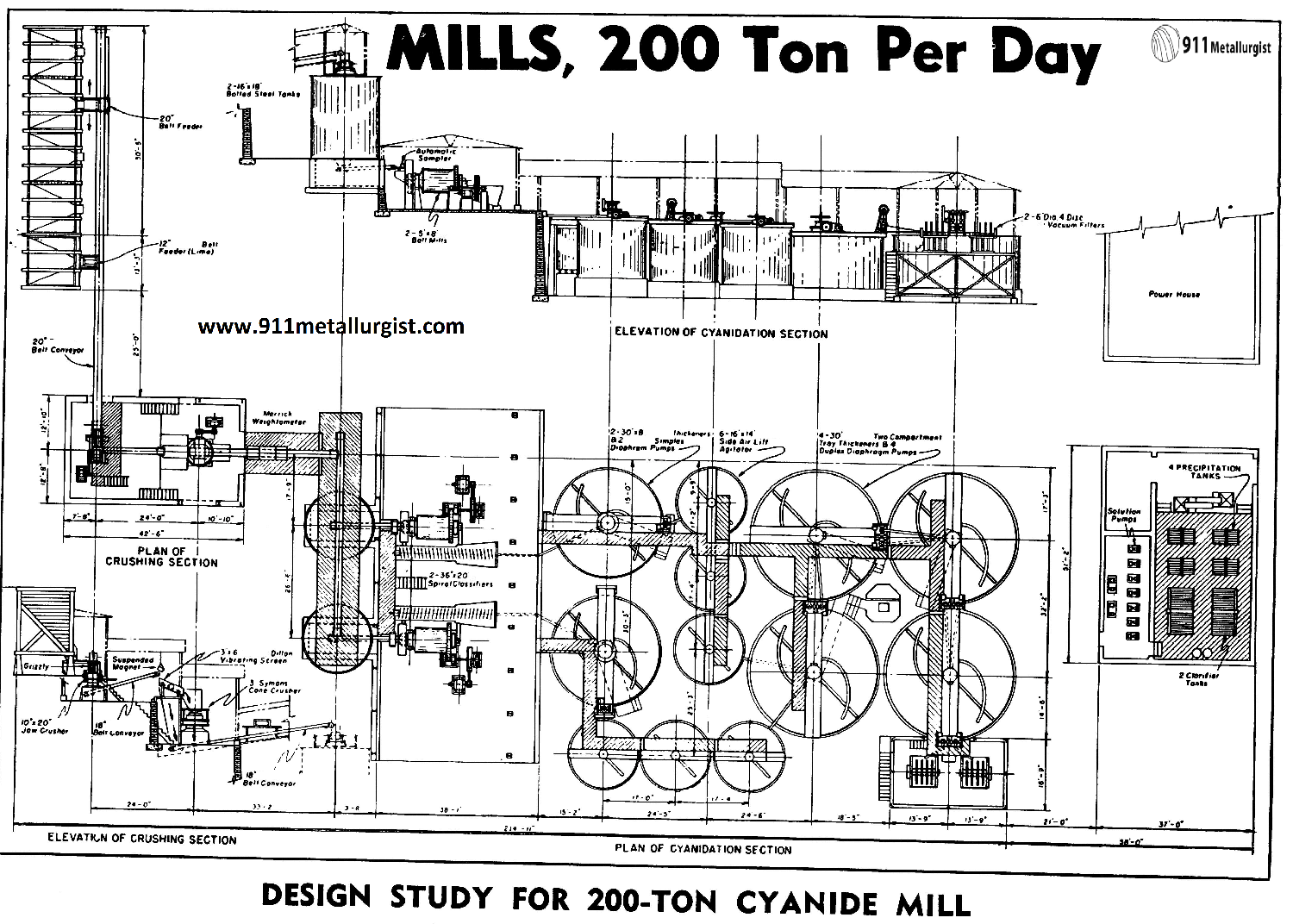

Small Gold Leaching Circuit Design

Improving The Gold Leaching Process Of Refractory Ores Using The Jetleach Reactor Sciencedirect

0 comments

Post a Comment